Brush machine, CNC brush tufting machine, CNC brush making machines, factory, exporter

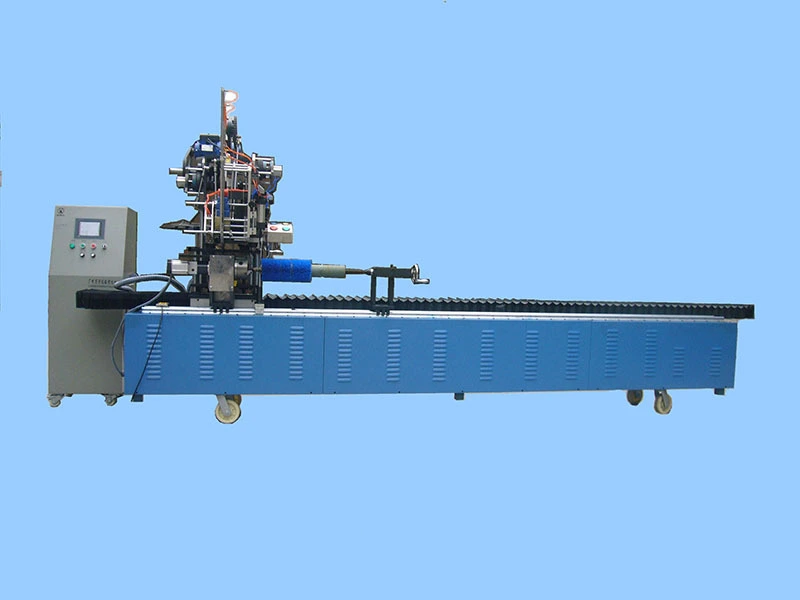

2 axis industrial cylinder brushes drilling and tufting machine WXD-2A2H-04

Features of 2 axis industrial cylinder brushes drilling and tufting machine WXD-2A2H-04

1) WXD-2A2H-04 is the specialized in making cylinder brush in both plastic and wooden brush block. It is drilling holes and tufting filament simultaneously.

2) With 5.4 inch touchable screen, the interface is available in various languages, such as Chinese, English, Spanish, French, etc, as required by clients.

3) With PLC (Programmable Logic Controller), this operates precisely with excellent stability.

4) The max length of working table is 2500mm, the max diameter of fixtures is 250mm.

5) Usually the operators make the program for cylinder brush in “ Parameter- Mode”, one the screen, operators can insert , delete, adjust, copy, separate and move holes, it is easy to operate.

Technical Parameter for 2 axis industrial cylinder brushes drilling and tufting machine WXD-2A2H-04

|

Standard Working Area of Working Table |

X-axis * Y-axis = 360°*2500mm |

|

Material of brush base |

Plastic, wood |

|

Material of brush filaments |

PP, PVC, PET, nylon, pig bristle, horse hair, tampico, etc |

|

Length of filaments (outside holes) |

10mm-120mm |

|

Diameter of holes |

3mm-5mm |

|

Colors of filament |

Either single color or two colors |

|

Maximum tufting speed |

5 holes per second |

|

Specification of machine body |

4.3m(length) * 0.9m (width) * 2.1m (height) |

|

Motor ( power system) |

Servo motors |

|

Data input for tufting positions |

Teaching mode: Operators manually puts tufting head into each hole, one by one, the position of these holes will be saved by computer one by one. By this way, all data for tufting position has been entered and saved. |

|

Digits mode: Operator manually enters digits (coordinates of X/Y axis) for tufting position. |

|

|

Touchable Screen |

With 5.4 inch touchable monitor controller, interface is in English or other languages required by clients, operating in dialogue-mode, which is quite simple and easy. |

|

Speed Adjusting |

Frequency-conversion stepless adjustable speed |

|

Qty of programs saved |

It saves totally 8000 holes |

|

Gross Weight |

Around 1000KGS |

|

Programming |

PLC (Programmable Logic Controller) |

|

Power Supply |

Either 3-phase 380V or 1-phase 220V, 50-60HZ,600W |

|

Replaceable Grippers |

FMS type. Operator could make other kinds of brushes, as long as he changes grippers. |

|

Tufting Method |

Anchor type or Staples type |

|

Packing |

Packed into wood cases. Wood case for machine body 4.3m*0.9m*2.1m Wood case for computer box 0.67m*0.67m*1.48m |

About us

Products Showroom

Video

Information Center