Brush machine, CNC brush tufting machine, CNC brush making machines, factory, exporter

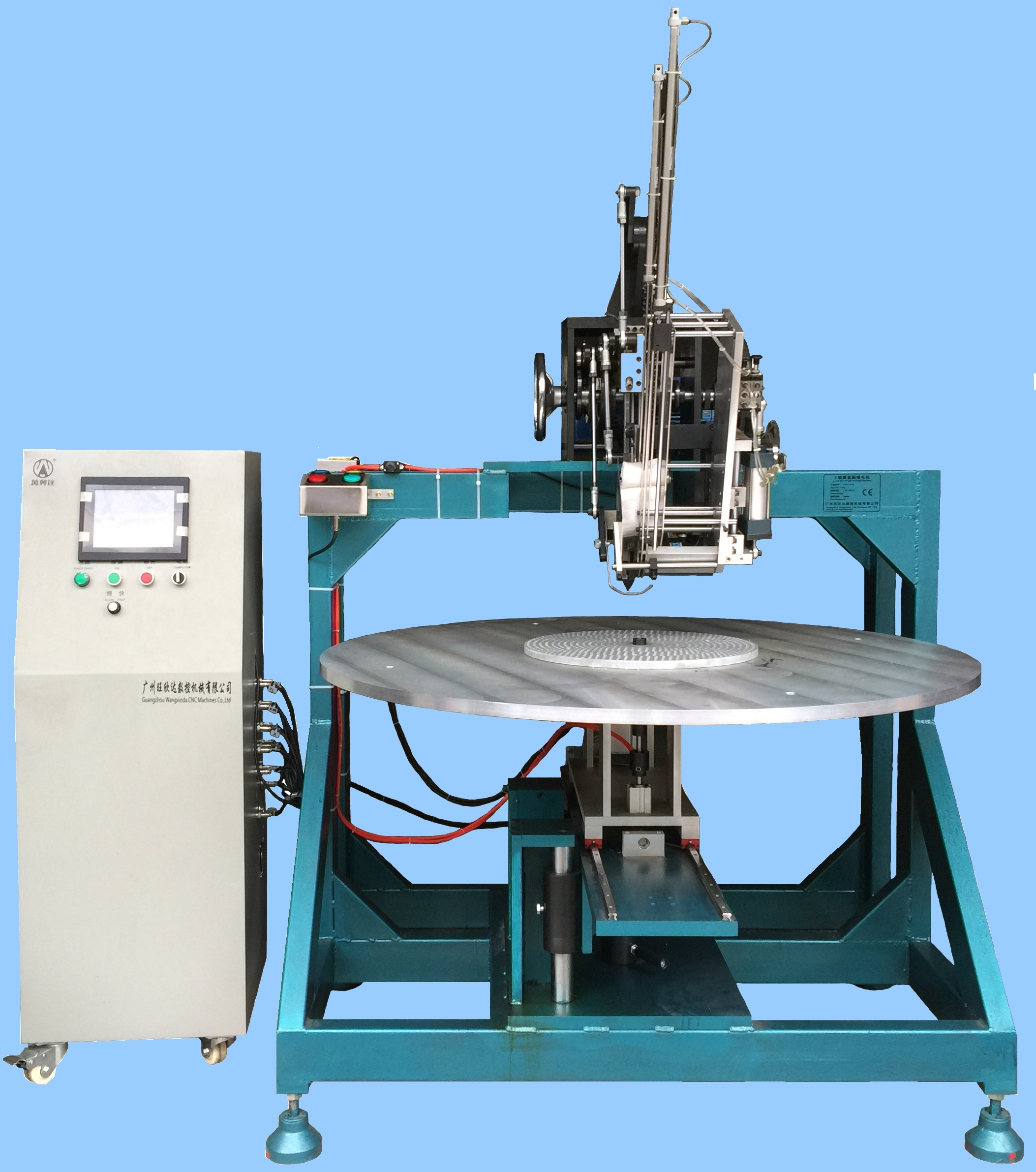

2-Axis Outsize Disc Brush Tufting Machine WXD-2A004

Features of 2-Axis Outsize Disc Brush Tufting Machine WXD-2A004 (staple type )

1> The 2 axis outsize disc brush tufting machine, was customerized by our clients, used to tufting

the disc brush at max 1200mm diameter.

Please noted that the brush block should be pre-holes in advance, the machines has tufting

filament function ONLY.

2> For the disc brush tufting machine, it tufts the filament straightly, without any angles.

If you would like to produce the disc brush with angles, please kindly view at 4 axis disc brush

tufting machine.

3> With the same working table to fixed the brush block, after select the brush design, it not only

produce the disc brush, but also the strip brush, plate brush.

4> In the Teach Mode, the operators enter the brush specification, the computer will make the

program for different brush item automatically.

Technical Parameter for 2-Axis Outsize Disc Brush Tufting Machine WXD-2A004 (staple type )

|

Standard Working Area of Working Table |

X-axis * Y-axis = 1200mm*360° |

|

Material of brush base |

Plastic |

|

Material of brush filaments |

PP, PVC, PET, nylon, pig bristle, horse hair, tampico, etc |

|

Length of filaments (outside holes) |

10mm-120mm |

|

Diameter of holes |

3mm-6mm |

|

Colors of filament |

Either single color |

|

Maximum tufting speed |

4 holes per second |

|

Specification of machine body |

1.8m(length) * 1.12m (width) * 1.75m (height) |

|

Motor ( power system) |

Servo motors |

|

Data input for tufting positions |

Teaching mode: Operators select the brush design and enter the brush dimension. By this way, all data for tufting position has been entered and saved. |

|

Digits mode: Operator manually enters digits (coordinates of X/Y axis) for tufting position. |

|

|

Touchable Screen |

With 5.4 inch touchable monitor controller, interface is in English or other languages required by clients, operating in dialogue-mode, which is quite simple and easy. |

|

Speed Adjusting |

Frequency-conversion stepless adjustable speed |

|

Qty of programs saved |

It saves totally 84 programs for making different brushes. |

|

Gross Weight |

Around 370KGS |

|

Programming |

PLC (Programmable Logic Controller) |

|

Power Supply |

Either 3-phase 380V or 1-phase 220V, 50-60HZ,600W |

|

Replaceable Grippers |

FMS type. Operator could make other kinds of brushes, as long as he changes grippers. |

|

Tufting Method |

Staple type (using Round Wire) |

|

Packing |

Packed into wood cases. Wood case for machine body 1.9m*1.2m*1.8m Wood case for computer box 0.65m*0.65m*1.5m |

About us

Products Showroom

Video

Information Center